How Timely Truck Radiator Repairs Can Prevent Your Long Haul Nightmare

Trucks are the backbone of the American economy, carrying an astounding 71% of all goods across the country, according to Wayfindr. Among the vital components ensuring these vehicles run smoothly are radiators, which regulate engine temperature and prevent overheating. Despite their importance, truck radiators often go unnoticed until a problem arises. Neglecting timely truck radiator repairs can lead to catastrophic engine failure, resulting in costly repairs and prolonged downtime on the road. Here, we'll explore the critical role radiators play in truck operation, the common issues drivers face, and the benefits of regular maintenance and timely truck radiator repairs.

The Function of Truck Radiators

The primary function of a truck radiator is to dissipate heat from the engine, a process crucial for preventing overheating during long hauls. Coolant circulates through the engine, absorbing excess heat, and then passes through the radiator, where it's cooled down. As the coolant flows through the radiator's thin tubes, air passes over the tubes, transferring the heat energy from the liquid to the air. This cooling process ensures the engine operates within a safe temperature range, maintaining optimal performance. Without this mechanism, the engine would overheat, leading to premature wear or even failure.

Temperature regulation is vital for engine performance and longevity. Engines work best within a specific temperature range, where components expand and operate smoothly. Too much heat can damage engine parts, reduce lubrication effectiveness, and increase the risk of a breakdown. In colder conditions, maintaining the right temperature helps prevent internal parts from contracting, which can cause damage upon startup. Radiators play a crucial role in achieving this balance by effectively managing the engine's thermal conditions.

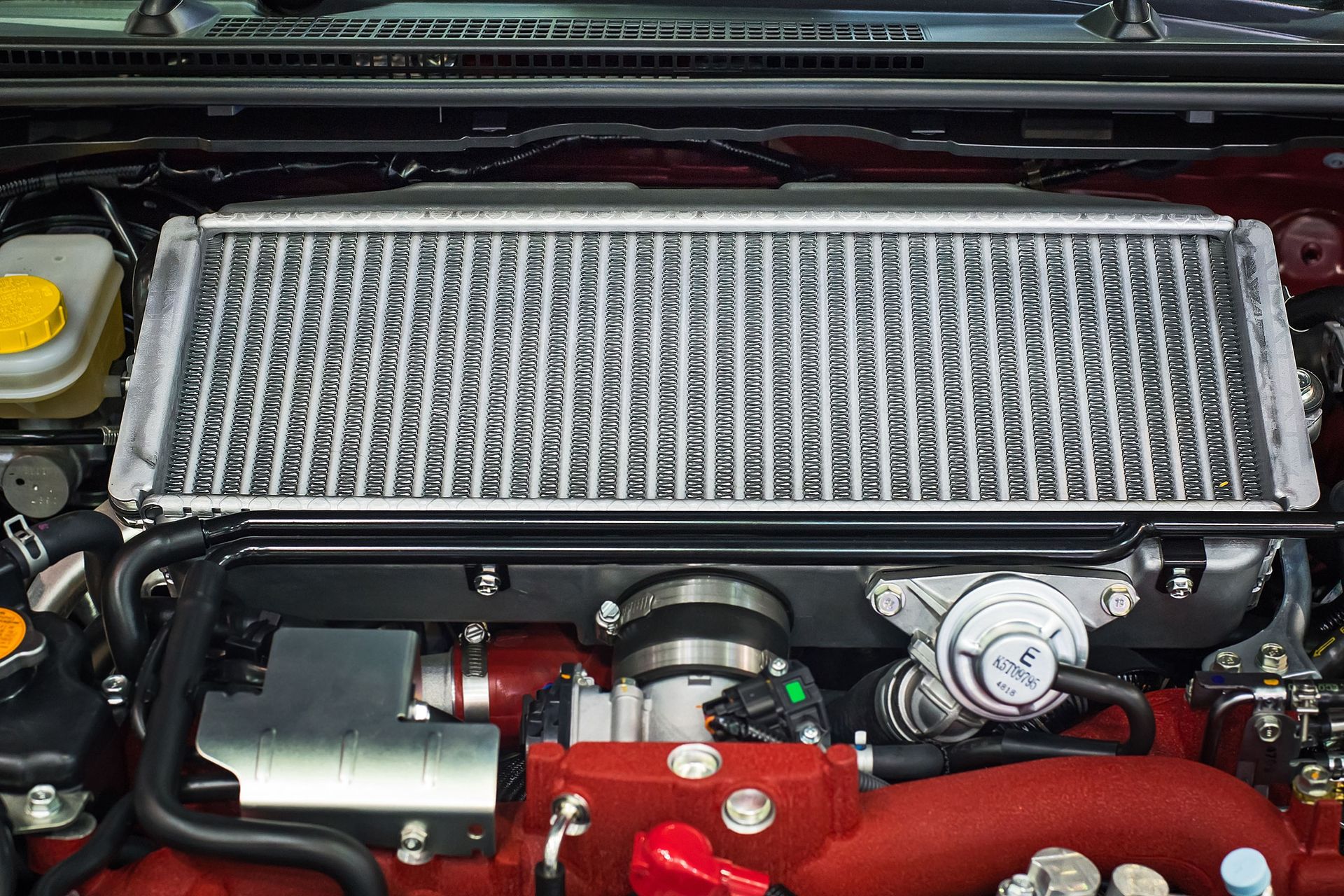

A typical truck radiator comprises several components, each playing a vital role in temperature regulation. The core, made of thin tubes and fins, serves as the primary area for heat exchange. The radiator cap helps maintain the pressure in the cooling system, allowing the coolant to flow efficiently. The thermostat controls coolant flow based on engine temperature, ensuring no energy is wasted. Without these components working in unison, the radiator fails to perform its function, leading to potential engine overheating.

While all vehicles require cooling systems, truck radiators face unique challenges due to the demands of long hauls and heavy loads. Unlike passenger cars, trucks often travel vast distances without the luxury of frequent stops, putting more strain on their cooling systems. Additionally, trucks carry heavier loads, which generate more engine heat than regular vehicles. In comparison, sports cars might have high-performance cooling systems designed for speed, but don't require the durability and endurance of a truck radiator. Therefore, truck radiators are specifically designed to withstand constant, heavy-duty use.

Understanding the warning signs of a failing radiator can prevent further damage and costly repairs. Common symptoms include coolant leaks, which might manifest as puddles under the truck. An unexplained drop in engine efficiency or unusual temperature fluctuations is another red flag. Steam or smoke emanating from the hood suggests severe overheating, likely due to radiator issues. Addressing these signs promptly can prevent a minor issue from escalating into major truck radiator repairs.

Common Radiator Problems Faced by Truck Drivers

Coolant leaks are among the most prevalent radiator issues truck drivers encounter. These leaks can stem from various causes, such as damaged radiator hoses or worn seals. A leaking radiator results in insufficient coolant flow, causing the engine to overheat. Such overheating can lead to warping and cracking of critical engine components. Timely detection and repair of leaks can save drivers from costly and extensive repairs down the line.

The build-up of debris in radiator fins and cores can severely restrict airflow, diminishing the radiator's cooling ability. Dirt, insects, and road grime accumulate over time, forming blockages that gradually impede performance. Without adequate cleaning, the radiator's efficiency drops, leading to engine overheating under normal conditions. Regular inspection and proper maintenance can prevent such build-up, ensuring the radiator functions optimally. A clean radiator core allows for effective heat dissipation and engine cooling.

Thermostat and radiator cap malfunctions are subtle issues that can have significant effects on the cooling system. The thermostat controls the engine's temperature by regulating the flow of coolant; if it fails to open or close properly, the engine can overheat. Similarly, a defective radiator cap fails to maintain the correct pressure in the cooling system, leading to potential leaks or inefficient cooling. Both these components, though small, play critical roles in maintaining temperature balance. Regular checks of these parts can prevent sudden breakdowns and maintain optimal engine performance.

The Importance of Regular Maintenance Checks

Scheduling regular maintenance checks is essential for preventing radiator-related issues. By establishing a routine, potential problems can be identified and addressed before they escalate into significant failures. A structured schedule outlines specific intervals for checking coolant levels, inspecting the radiator for leaks, and cleaning debris from radiator fins. Consistent maintenance provides a roadmap for prolonged radiator efficiency and truck performance. This proactive approach minimizes the risk of unexpected breakdowns and disruptions.

A comprehensive radiator checkup should cover several key areas to ensure optimal performance. Visual inspections can identify leaks, corrosion signs, and debris blockages. Coolant level checks and testing the quality of the coolant are crucial for maintaining proper temperature regulation. Ensuring the radiator cap and thermostat function correctly prevents pressure imbalances. Addressing these components in regular checkups ensures the radiator runs efficiently under various operational conditions.

Advanced diagnostic tools and technology have revolutionized truck radiator maintenance. These tools quickly identify potential issues, such as leaks or blockages, with high accuracy, reducing the need for lengthy inspections. They analyze coolant quality and temperature fluctuations, providing data for informed maintenance decisions. By leveraging technology, truck operators can efficiently plan and execute maintenance tasks, improving overall fleet performance. Embracing these innovations enhances the proactive maintenance of truck radiators.

Benefits of Timely Repairs and Upkeep

Timely radiator repairs significantly enhance engine performance by preventing overheating and ensuring efficient temperature management. Consistent temperature regulation allows for optimal fuel combustion and reduces engine stress. A well-maintained radiator minimizes power loss by helping engine components work harmoniously. As engine efficiency improves, drivers enjoy smoother operations and enhanced responsiveness. Investing in regular radiator upkeep directly improves engine performance and operational efficiency.

Regular radiator maintenance extends the overall lifespan of a truck, safeguarding against premature engine failures. Addressing radiator issues promptly reduces the risk of overheating and the associated damage to engine components. As a result, the truck operates efficiently for longer periods, delaying the need for costly replacements. Proper radiator care aligns with the broader goal of maximizing asset longevity. Truck owners who prioritize timely maintenance enjoy a longer vehicle lifespan and better return on investment.

A well-maintained radiator is crucial for preventing costly, unexpected breakdowns during long hauls. Catching issues early through regular maintenance avoids sudden radiator failures that leave trucks stranded. The costs of emergency repairs, towing, and potential cargo spoilage can be substantial. Routine care reduces the likelihood of such breakdowns, ensuring that operations run smoothly and on schedule. Prioritizing radiator health is a direct investment in minimizing operational disruptions and costs.

Truck radiators play an indispensable role in preventing overheating and ensuring engine efficiency during long hauls. Neglecting timely repairs and maintenance can result in dramatic consequences, including costly breakdowns and prolonged downtime. By prioritizing radiator health, truck operators can enhance engine performance, extend vehicle lifespan, and maintain reliable operations. Through a commitment to regular maintenance, leveraging diagnostic technology, and choosing the right specialists, the trucking industry can avert potential disasters. Ultimately, focused

truck radiator repairs can support smooth transportation, aligning with both operational goals and economic interests. Contact Mobile Diesel Electric Radiator and A/C today for more information.

Share On: